Product Overview:

CoreClad® textured, ACQ treated plywood cladding offers superior strength, durability, and reliability. With sheets up to 3 metres long and no requirement to retreat cut ends, CoreClad® is fast and easy to install.

Plywood veneer is peeled from the log on a rotary lathe, dried, treated then manufactured into plywood by placing veneers in a perpendicular orientation. Sheets are bonded with a permanent phenolic resin which is commonly referred to as a Type 'A' structural bond. The bond will not break down under heat, wet, or cold conditions. The resulting sheets are then machined, rough-sawn, grooved and ship-lapped to form the finished cladding sheet.

CoreClad® has a 'pass™' (Product Assurance Supplier Statement). A pass™ makes a clear, rigorous statement that CoreClad® complies with all the necessary regulations and legislation. It also summarises CoreClad's purpose, the scope of its use and any limitations.

FEATURES AND BENEFITS OF CORECLAD®

- Each veneer is treated before it is manufactured into CoreClad®. This ensures the cladding is treated to the core. This improves durability as well as speeding up installation, as cut ends do not need to be re-treated.

- Available in 2440, 2745, and 3050mm length sheets* potentially eliminating the need for flashings, saving time and money.

- Available with a band-sawn face for a rough textured finish, with, or without grooves (Groove150 or Textured), in natural or primed.

- Made from high-strength plantation pine (F14) and manufactured to AS/NZS 2269:2012. It is third-party certified by the Engineered Wood Products Association of Australasia (EWPAA).

- Meets the Durability requirements of the NZBC for claddings.

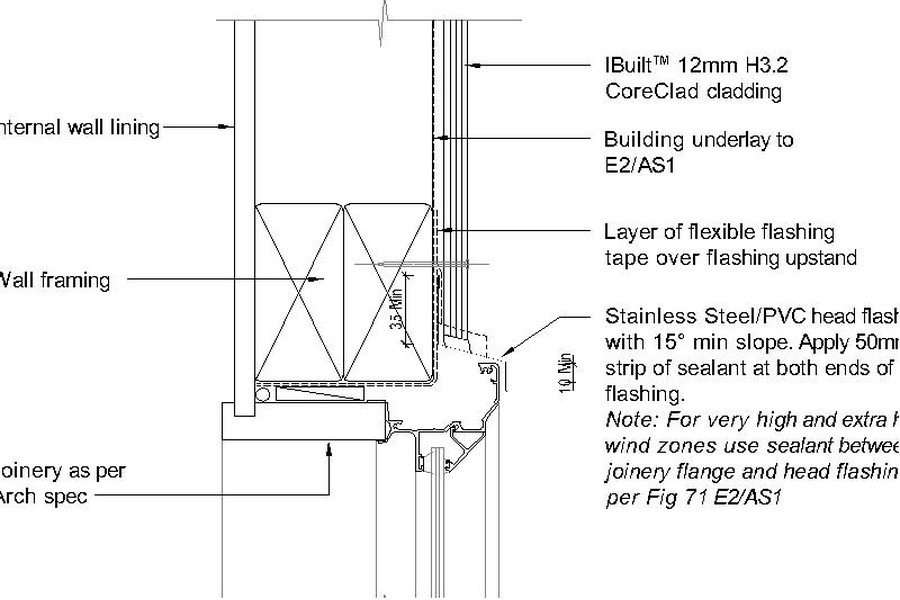

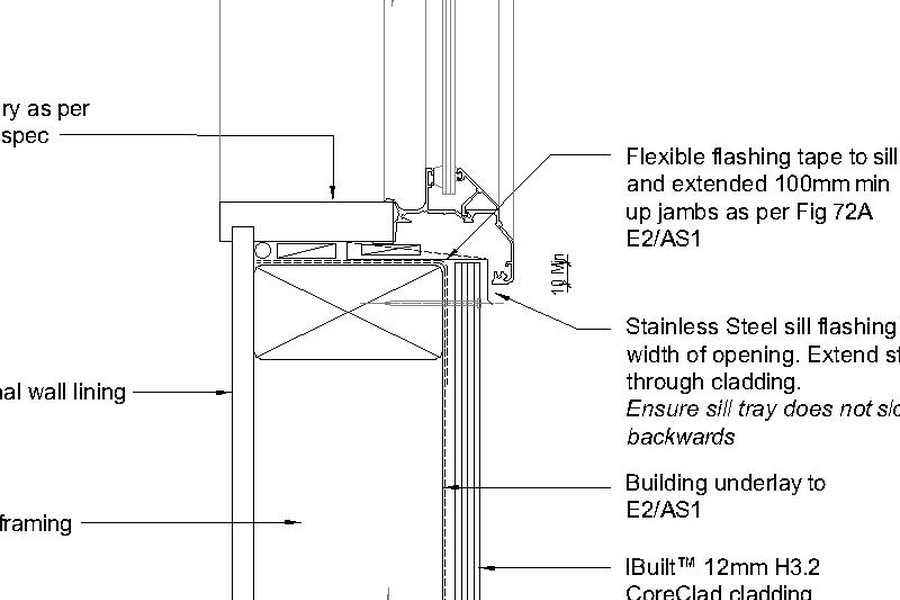

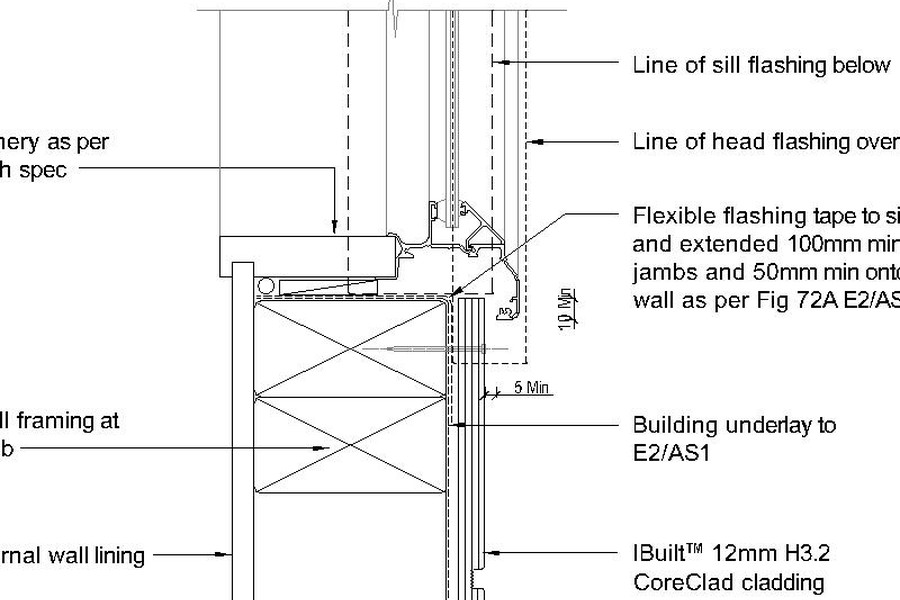

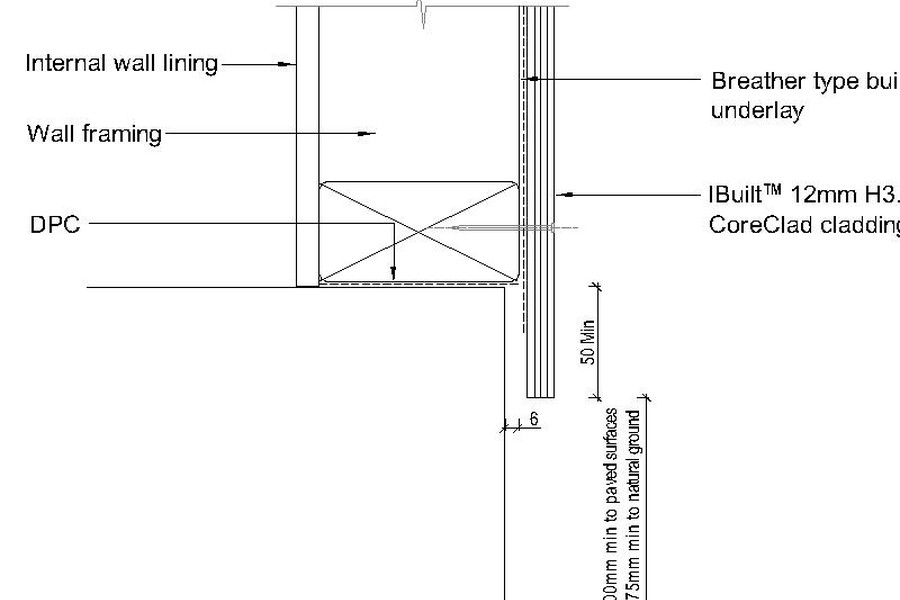

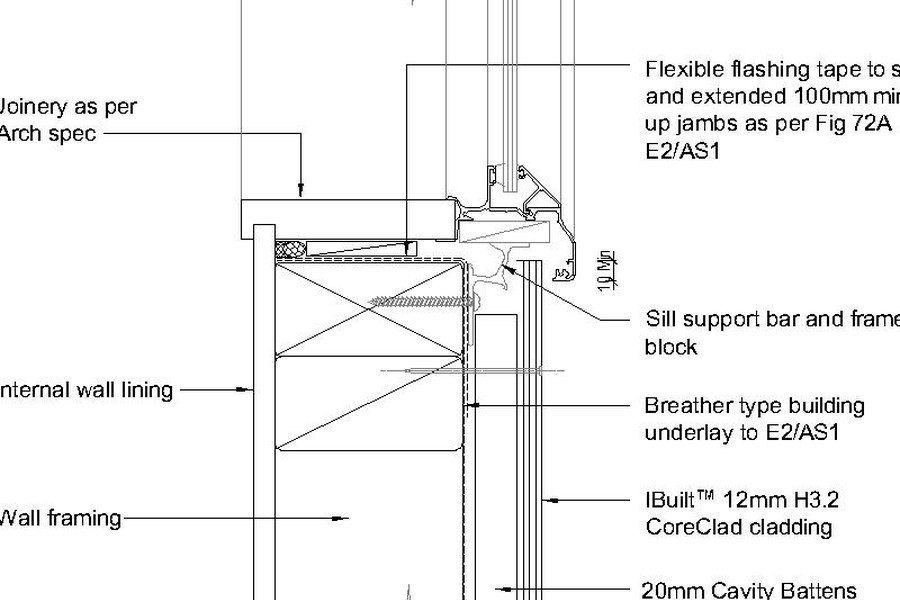

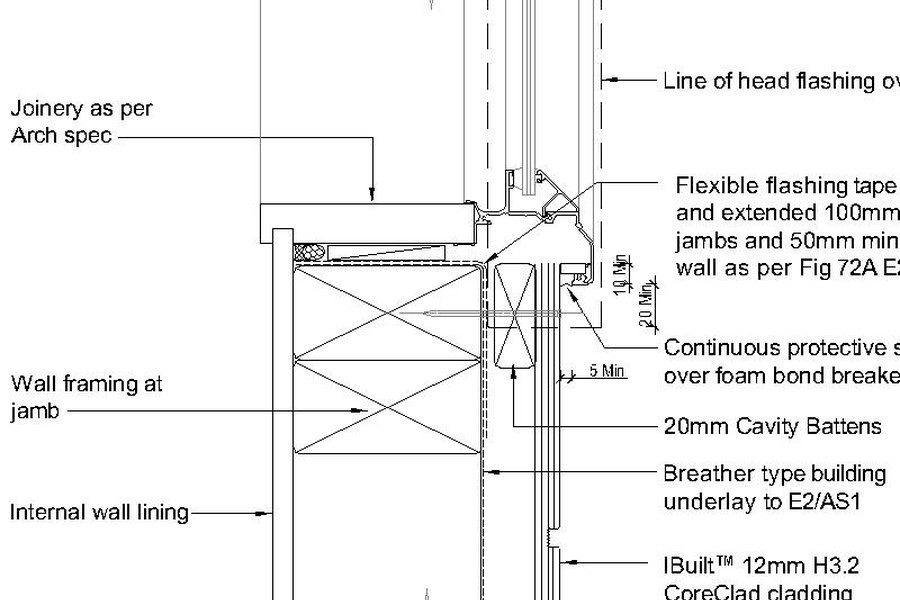

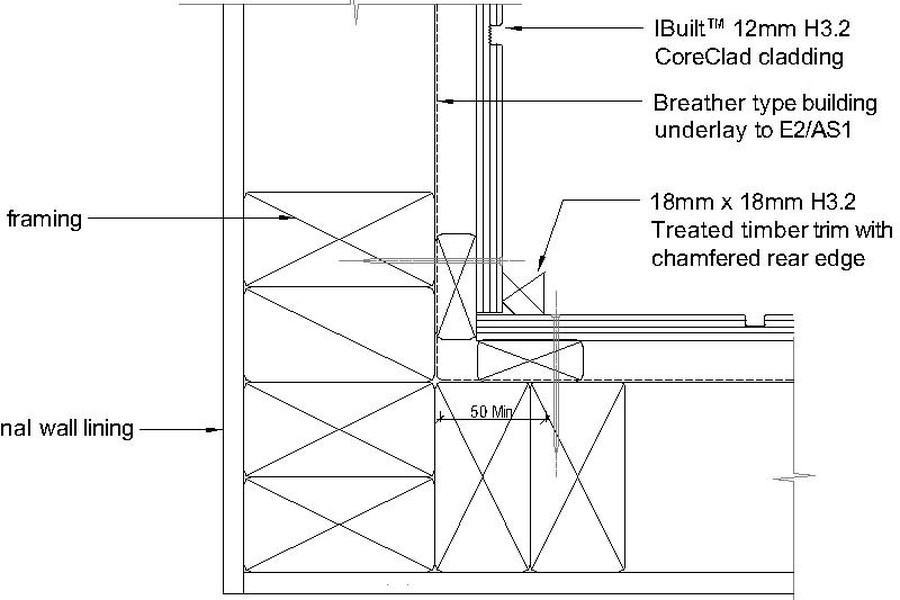

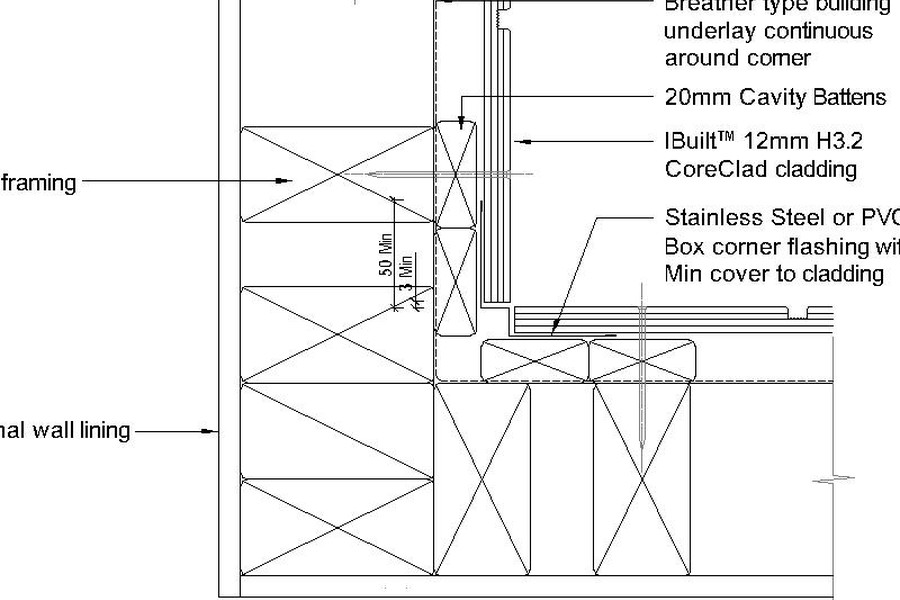

- Install to E2/AS1 NZBC.

CORECLAD® PRIMED

FEATURES AND BENEFITS

- CoreClad® Primed uses a factory applied premium acrylic primer which provides an optimal base coat for acrylic topcoat systems.

- This eliminates the need for a primer coat to be applied once installed, saving time.

- Once installed, the primer provides protection against moisture, allowing the topcoats to be applied sooner.

- Face, edges, and bottom 150mm of the back of the sheet are fully primed, allowing for faster onsite installation.

- CoreClad® Primed can be painted immediately after installation.

* A scarf joint is used to joint 2440mm long sheets with either a 305 or 610mm extension to produce 2,745mm or 3,050mm length sheets. The scarf joint has a visible dark line going across the panel and the two sections may have colour differences.

Don’t be afraid of the dark - Painting Dark Colours

One of the distinct advantages of using IBuilt™ CoreClad® Primed as exterior cladding is the ability to paint it in any number of today’s fashionably dark colours. Even black.

However, to ensure maximum product performance, long life and to have dark coloured exterior cladding look its best year after year, it is critical you follow these criteria:

- CoreClad® Primed must be used. Every sheet is pre-primed at the factory to ensure correct primer coverage and opacity is achieved.

- Use Dulux Weathershield® Colourguard™ or Resene CoolColour™ for best results and always follow paint manufacturer’s instructions. The Resene CoolColour™ system requires Resene's specified primer to be used over the top of the primer coating on CoreClad® Primed.

- 3 topcoats must be applied. Not only will your exterior cladding look better it will perform better too.

- Carry out regular paint maintenance. The use of dark paint colours requires an increase in coating maintenance over the lifetime of the cladding, compared to lighter colours.

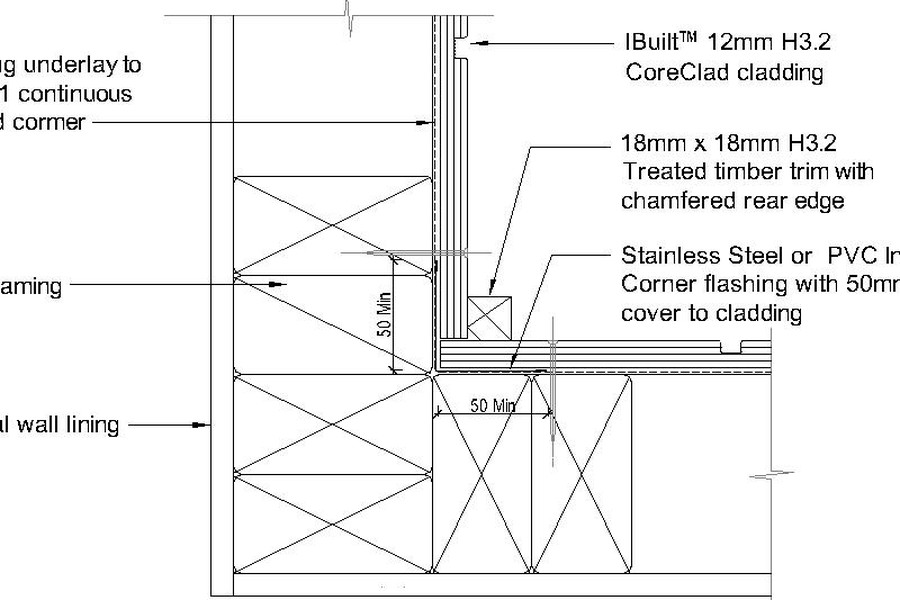

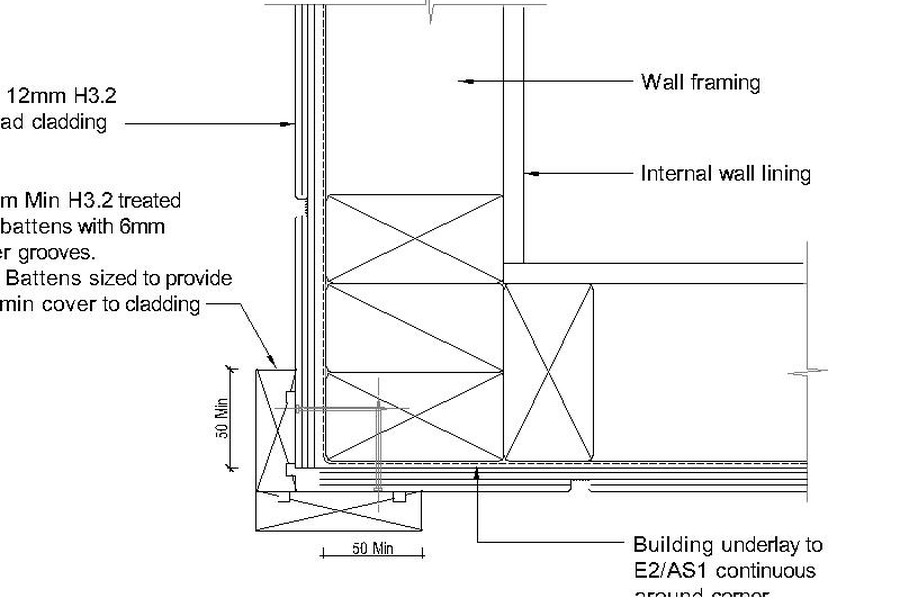

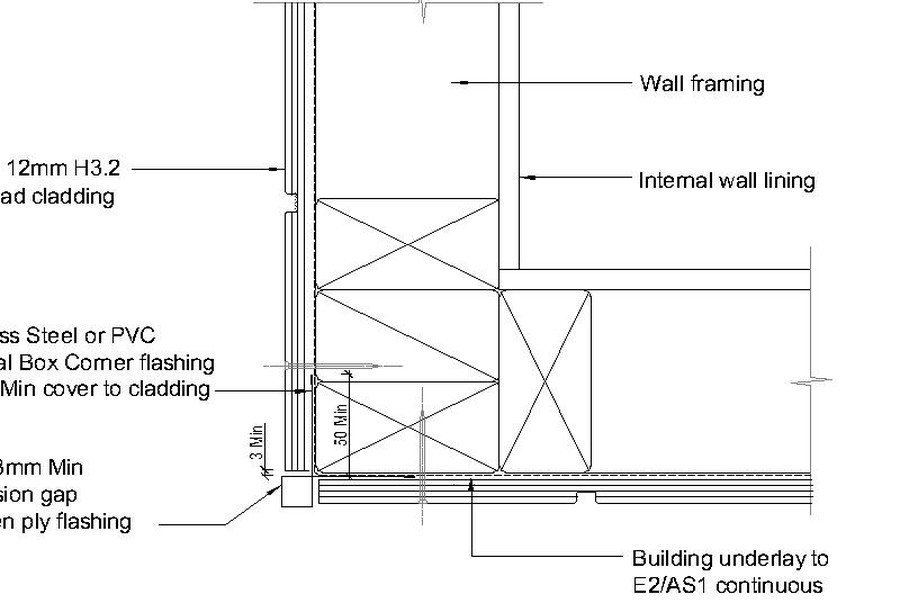

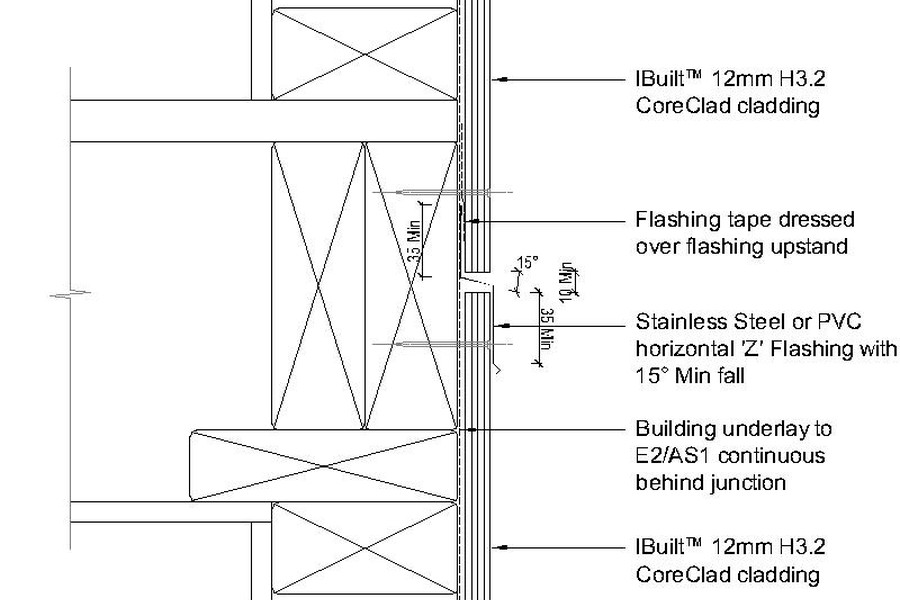

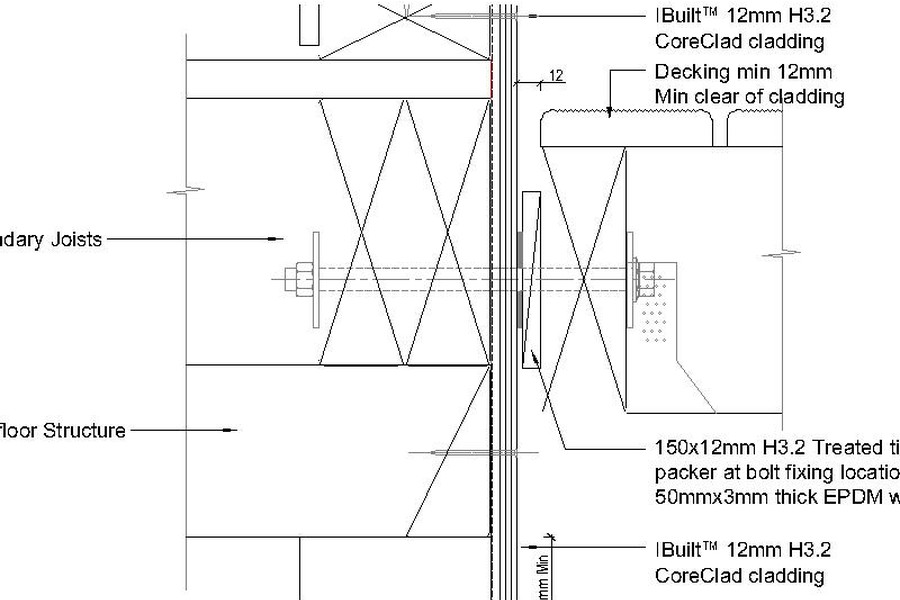

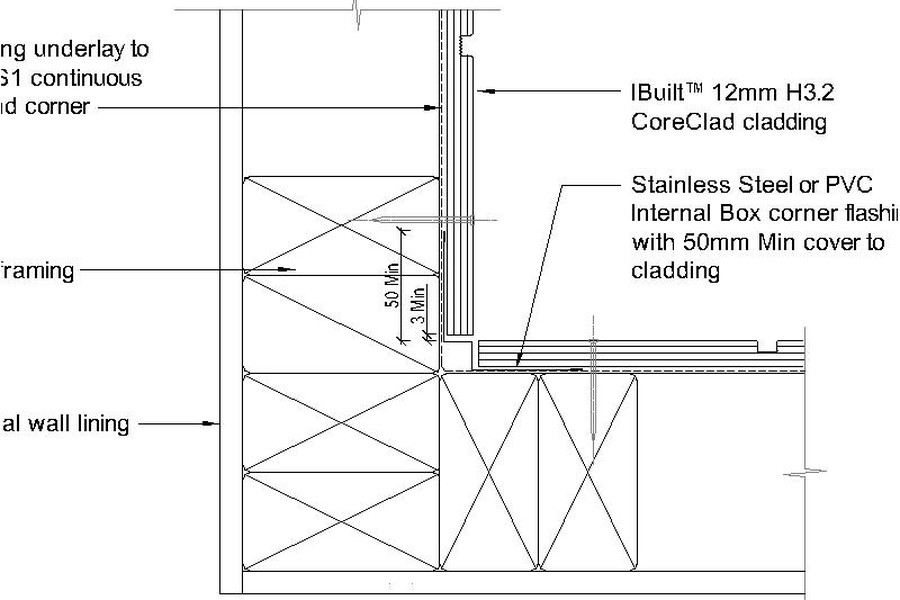

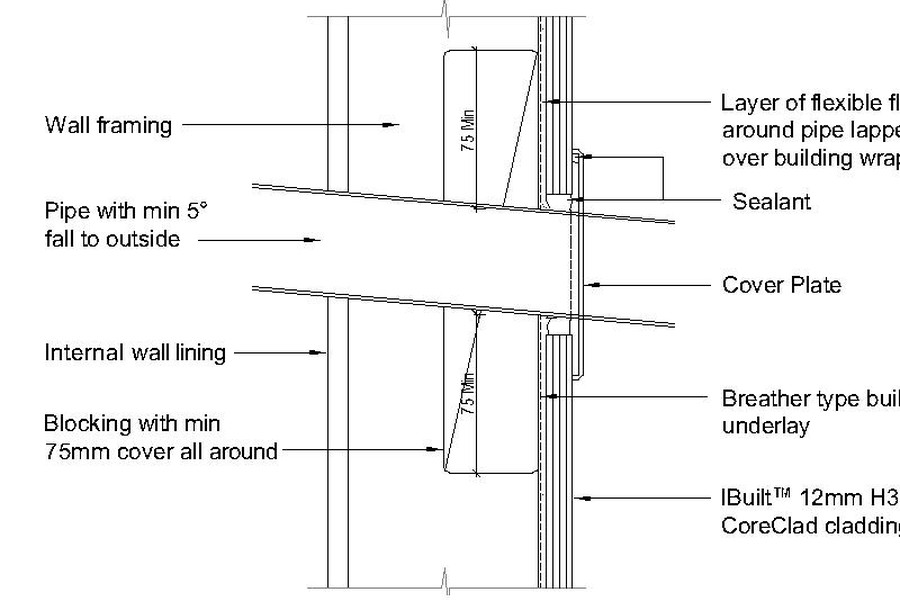

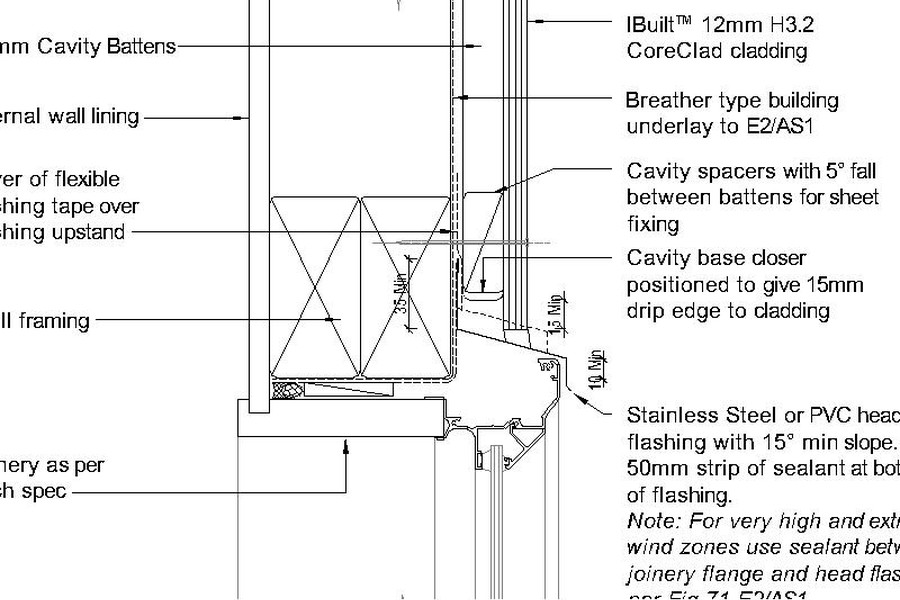

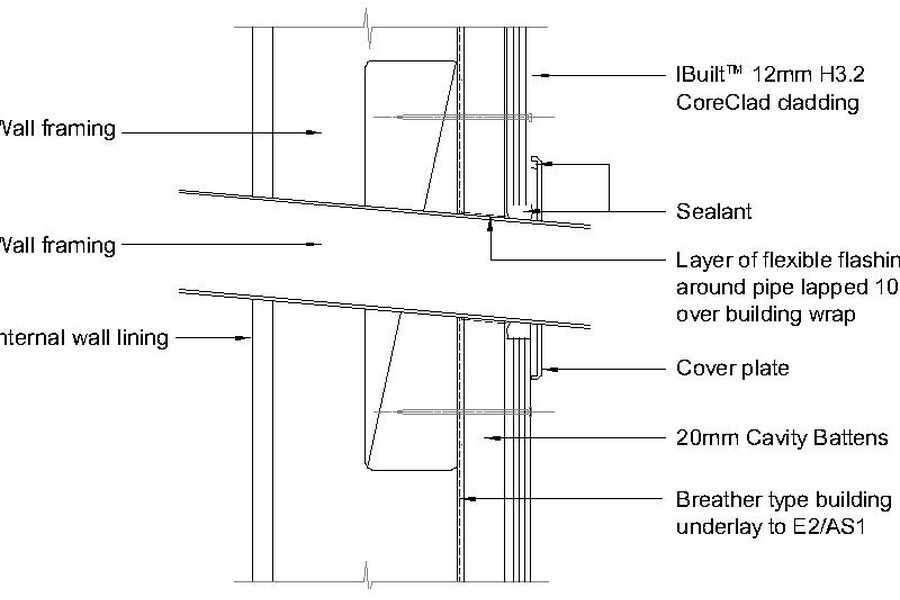

Stainless Steel Flashings

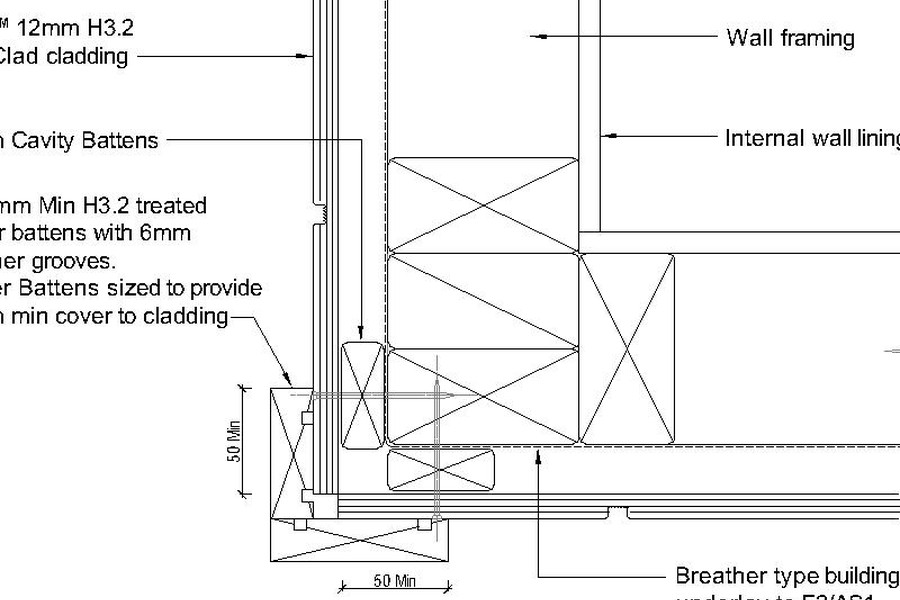

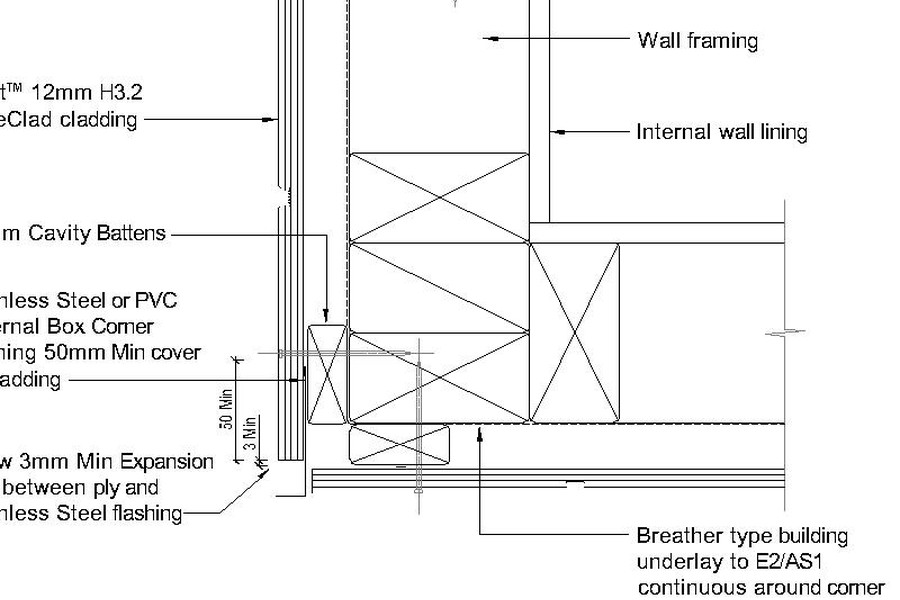

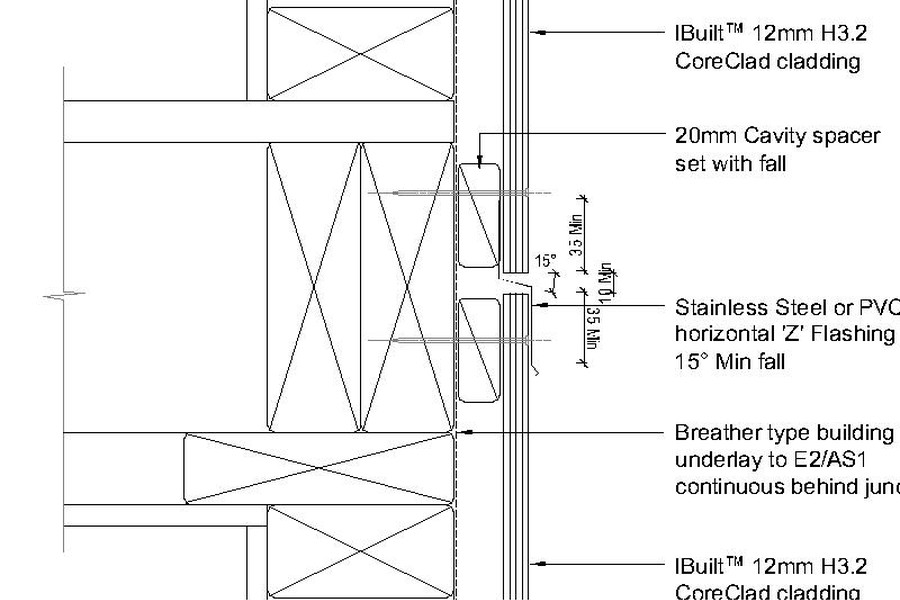

We’re now supplying a range of 304 and 316 grade stainless steel flashings to make things easier for customers using CoreClad®. Since CoreClad® is ACQ treated you need to use either PVC or stainless steel flashings. This is to minimise the possibility of bi-metallic corrosion. Refer to the Stainless Steel Flashings Flyer below.

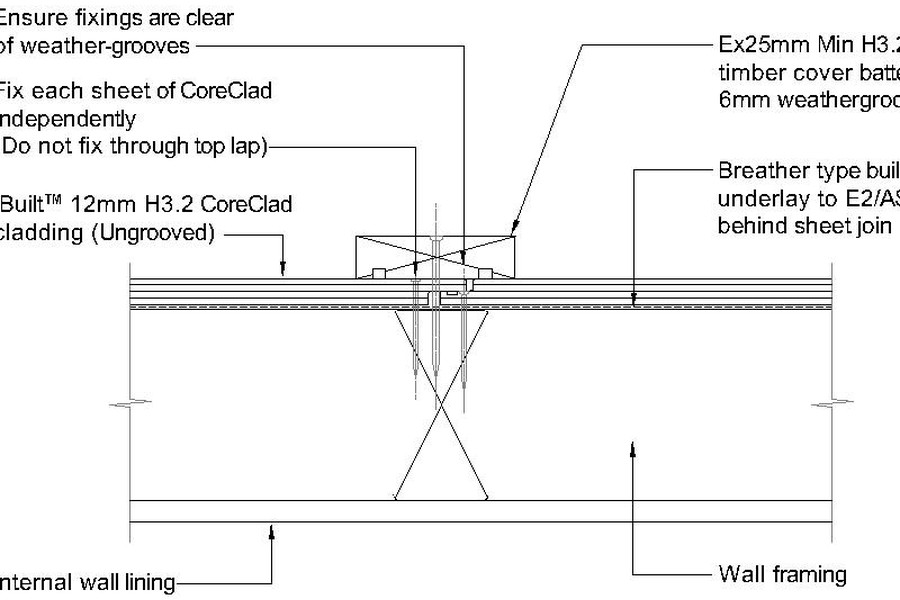

IMPORTANT INSTALLATION REQUIREMENTS

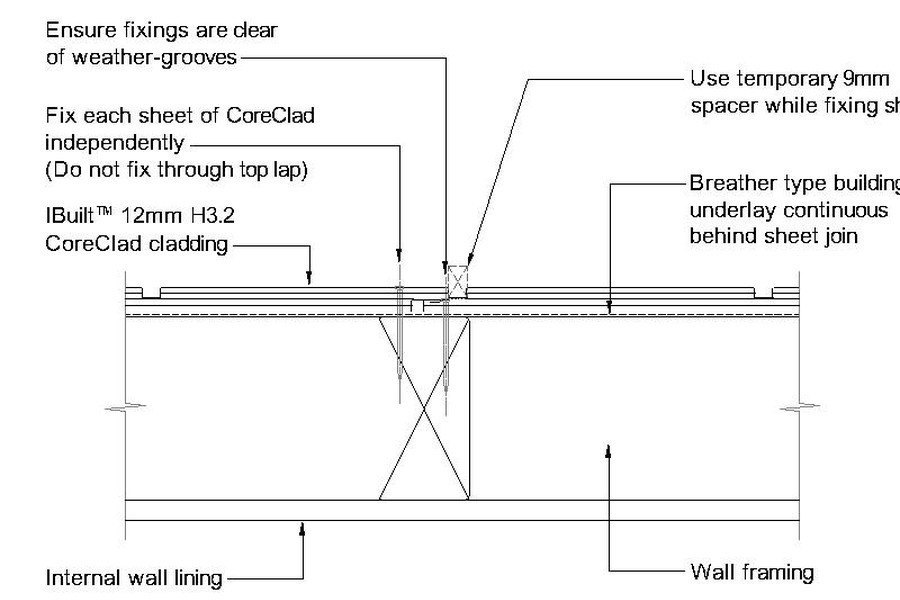

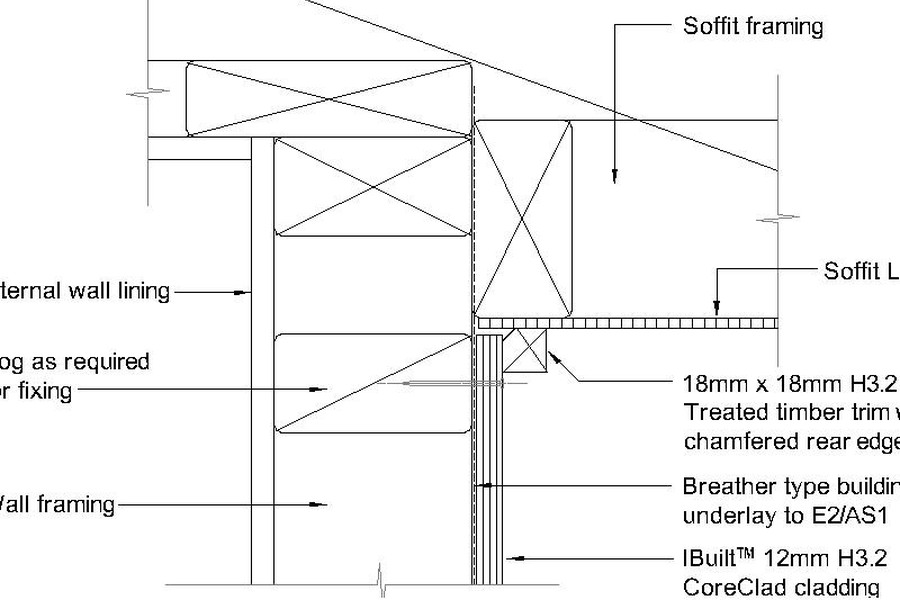

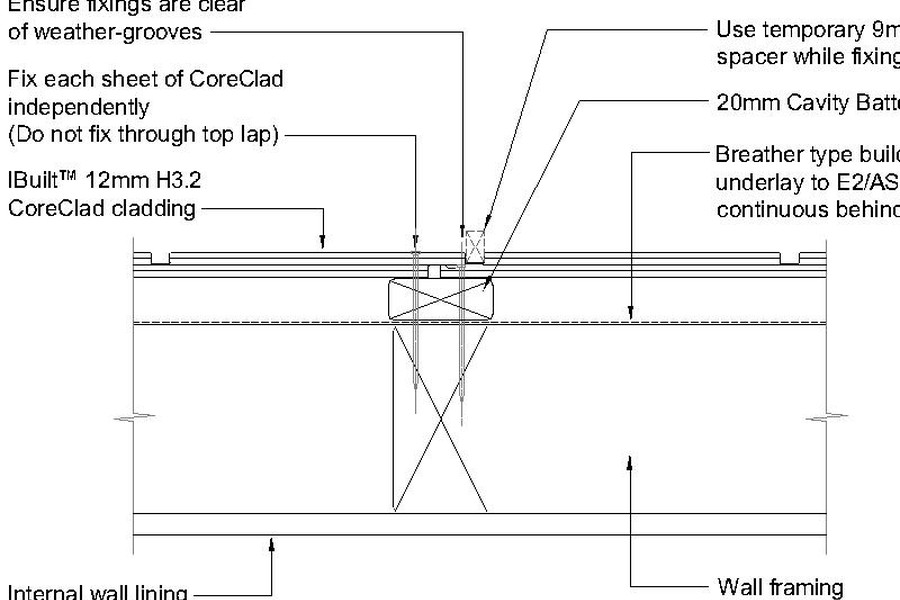

To ensure CoreClad® performs as required, the following must be carried out during installation.

- Product must be fully dry (15% or less moisture content) before priming or painting.

- Nails must not be over-driven.

- All factory and cut edges, including 150mm up rear of sheet must be fully primed before painting.

Failure to follow these requirements may affect the long term durability and void warranty.

IBuilt™ CoreClad® is manufactured by PNG Forest Products

PO Box 76412, Bulolo, Papua New Guinea

Product Literature:

Installation Details:

Certificates:

Get in touch:

I-Built products are available on order from all major building supply outlets throughout New Zealand. Please feel welcome to request product samples - or additional information - using the enquiry form below:

Gallery

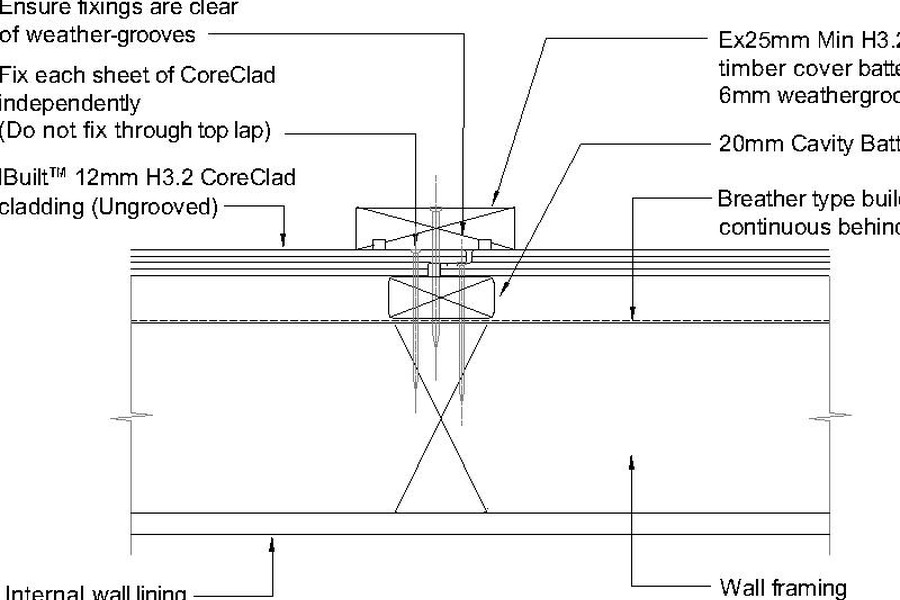

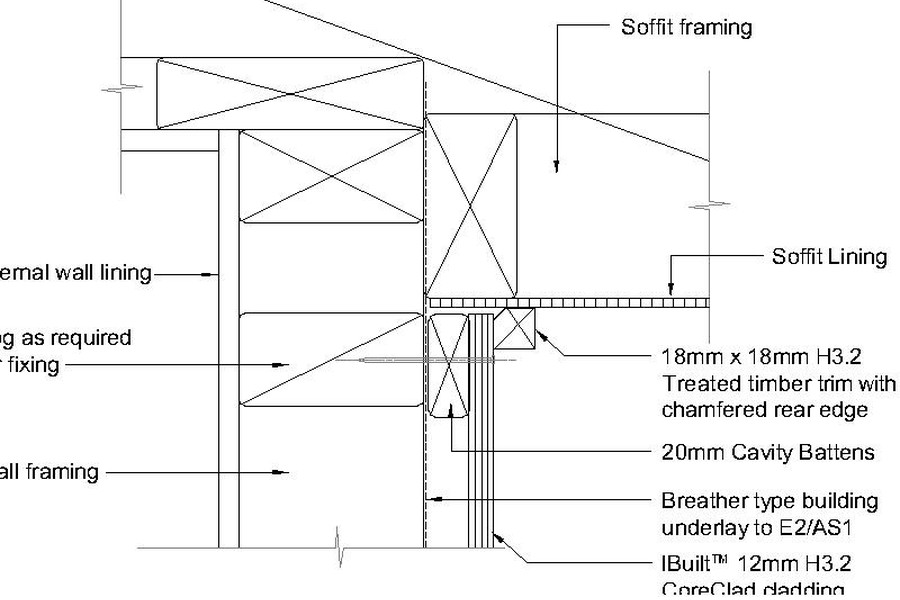

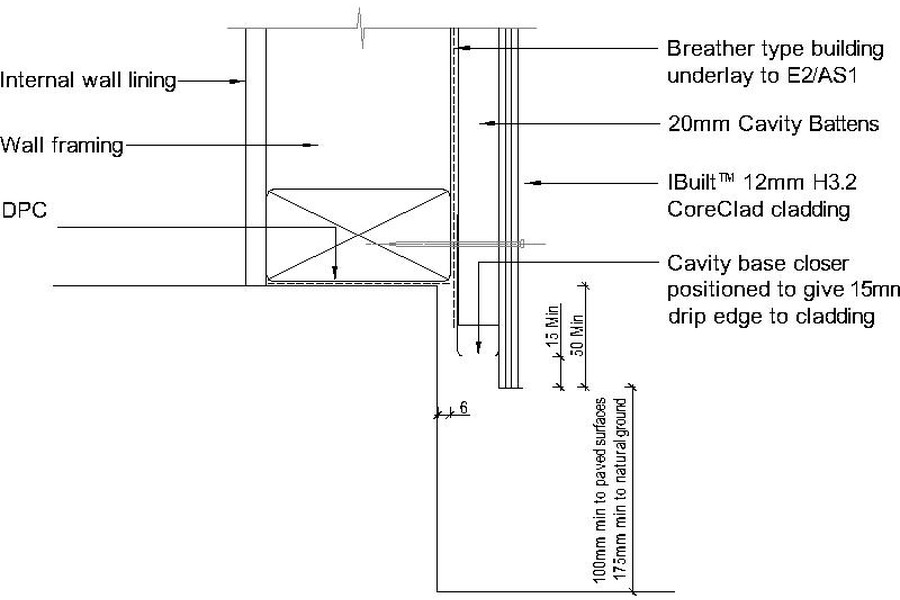

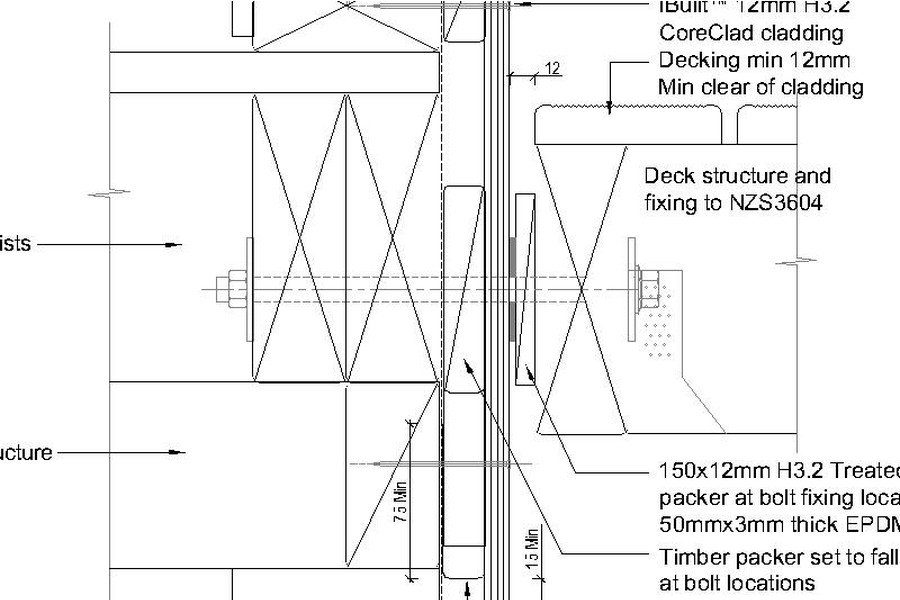

CAD Details

Start using our products in your designs. Download CAD files or PDFs of construction details for our product range Search & download

Product Brochures

Download PDF versions of our latest brochures to make selecting the right product easy. Browse our selection

Design & Layout Service

Need help? Make use of our experienced design & layout team for your next project Learn more