Product Overview:

Engineered for the Unimaginable

IBuilt FloorPly14® is NZ’s strongest rated pine plywood flooring, engineered for the things you’ve possibly never thought of.

The high strength F14 plywood results in a stiffer floor with less deflection between joists, providing a solid, durable feel.

Certified Strongest

No other pine plywood flooring compares to our F14 stress grade. Manufactured by PNGFP to AS/NZS 2269.0:2012 Plywood Structural standard. FloorPly14® is certified by the Engineered Wood Products Association of Australasia (EWPAA) meeting the highest product quality and performance standards.

Certified Sustainable

FloorPly14® holds PEFC (PEFC/40-31-20) chain of custody certification.

PEFC (Programme for the Endorsement of Forest Certification) is a chain of custody system that tracks the wood from source to the final product, ensuring that the wood fibre contained in the finished product originates from sustainably managed forests.Product Information

Learn more about FloorPly14® specification - available sizes & grades, plus installation guides below.

Specification

| Sheet Sizes | 2400 x 1200mm | |

| Edge Profile | Tongue & grooved (T&G) with a plastic tongue | |

| Grades | CD Grade

Carpet Grade (a cost-effective option where carpet is to be used) | |

| Thickness | CD Grade: 15mm, 17mm, 19mm, 21mm, 25mm

Carpet Grade: 19mm, 21mm | |

| Species | Hoop Pine | |

| Applications | Flooring, roofing and membrane substrates. |

FloorPly14® Plywood Characteristic Properties

| Stress Grade | Characteristic Strength, Mpa |

Short Duration average Modulus of Elasticity, Mpa (E) |

Short Duration average Modulus of Rigidity, Mpa (R) |

|||

| Bending (f'b) |

Tension (f't) |

Panel Shear (f's) |

Compression (f'c) |

|||

| F14 | 36 | 22 | 4.8 | 27 | 12000 | 625 |

Treatment

Treated FloorPly14® is available in H3.2 CCA. The plywood is impregnated to H3.2 CCA (Copper Chrome Arsenic) hazard class treatment in accordance to AS/NZS 1604;1:2021 (Specification for preservative treatment). H3.2 CCA treatment leaves a green appearance on the ply sheet.

Note: When using treated plywood it is good practise to re-treat cut ends with a brush on preservative such as Metalex.

Glue bond

FloorPly14® utilises a Phenolic Formaldehyde Type A exterior grade adhesive that provides a permanent bond between each veneer once cured. All FloorPly14® plywood achieves an 'E0' emission rating (less than 0.3mg/l) which is the lowest emission class rating that can be achieved.

Substrate use

FloorPly14® can be used as a substrate for permanent weather barrier systems such as roofing shingles, tiles, and under membrane systems. A minimum C grade face is recommended for roof and deck membrane systems. Refer to the membrane system treatment requirements.

Construction exposure

Plywood can withstand normal weather exposure for up to 3 months during construction. If plywood is intended to be left exposed, it is recommended that it is protected during construction to minimise any staining or weathering. Where excessive wetting has occurred, all timber should be allowed to return to normal moisture content levels (18%) before being closed in.

Limitations of use

Untreated plywood must not be used externally or in high moisture areas. H3 treated plywood must not be in contact with the ground. Ensure only compatible materials/fixings are in direct contact with CCA treated plywood.

Handling and storage

FloorPly14® should be delivered dry and undamaged from freight and handling. All panels should be inspected upon the delivery. Ply should be lifted off the truck by hoist or hand.

Stack panels horizontally, dry and 100mm clear off the ground and supported on dry, clean timber bearers at a maximum of 900 mm centres and at both ends of the panels.

Keep ply panels dry at all times, either by storing within an enclosed building or use an additional weatherproof cover as a secondary to packaging wrap if stored outside. Ensure that there is sufficient air flow to avoid condensation. Avoid storing over standing water or vegetation.

Health and Safety

When machining plywood always wear safety glasses, and if wood dust exposure is not controlled, wear a class P1 respirator. To avoid skin irritation and the risk of splinters, wear comfortable work gloves. Wash hands with mild soap and water after handling panels.

Installation Guide

Installation on floor joists

When installing FloorPly14® on a floor joist system it must be installed perpendicular to the run of joists. Sheets must be fully screwed and glued using a suitable construction adhesive. Construction glue must be used to the full perimeter of the sheet and to all intermediate joists. Fixings generally at 150mm centres to the perimeter of the sheet and at 300mm centres to intermediate supports. Where flooring plywood has been specified as a diaphragm system, install as per the engineer’s details.

Fixings

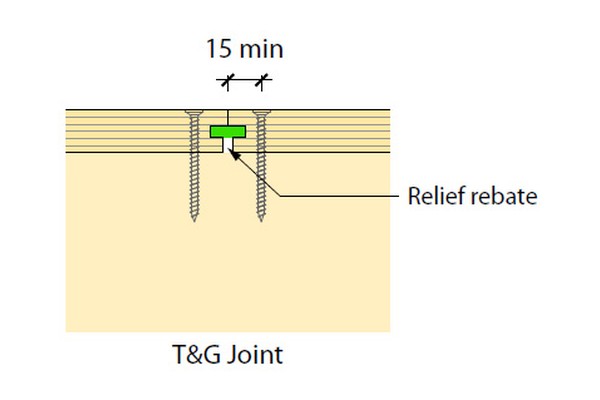

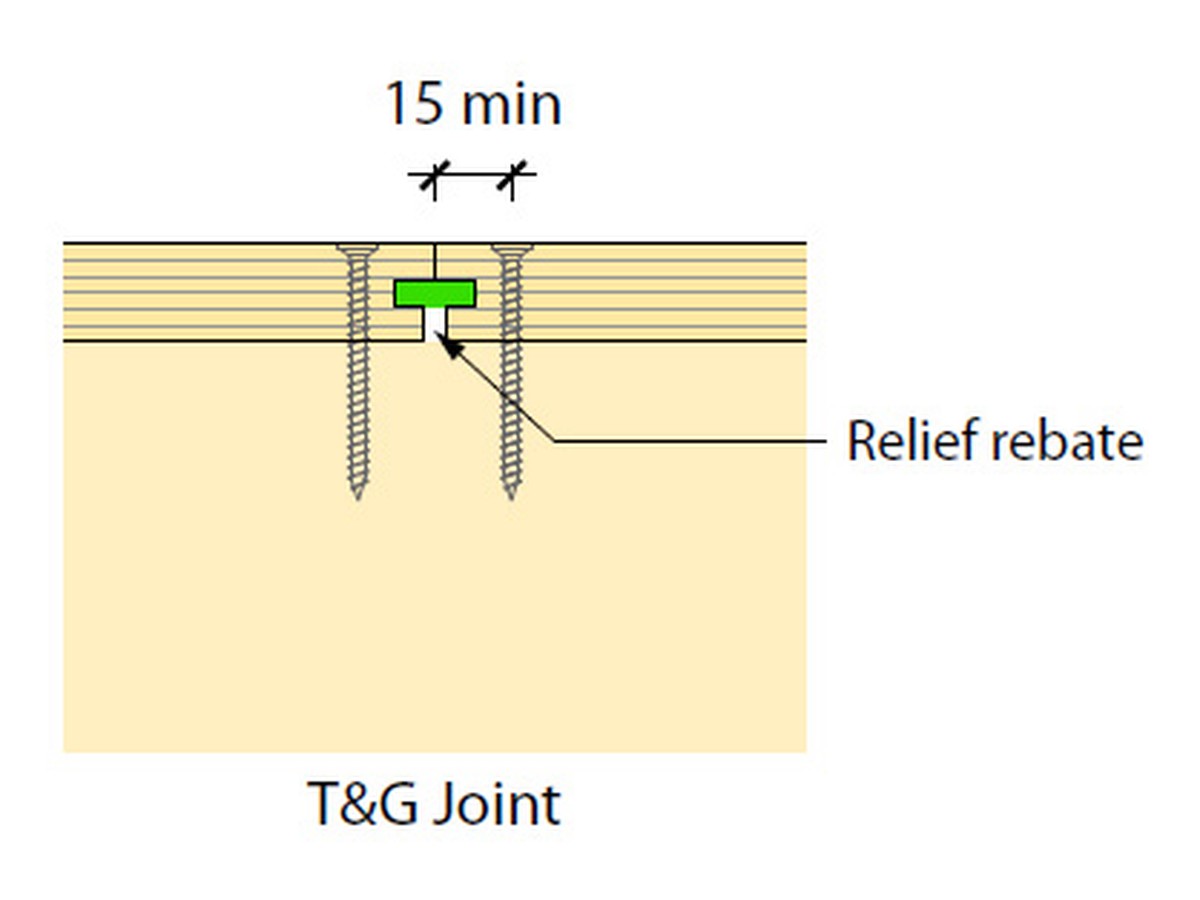

Fixings should be 7mm min from sheet edges for square edge panels and 15mm minimum from tongue and grooved edges. Corrosion resistant fasteners (hot dip galvanised steel) must be used when using treated plywood. Stainless steel fixings may be required depending on the application or exposure zone. Stainless steel fixings must be annular grooved.

Expansion Gaps and Blocking

The tongued edge can be installed with no gap as there is a relief rebate on the back face of the sheet which allows for expansion and contraction. Tongue and groove joints do not require additional support under the sheet edges unless specified by the engineer or designer, or in a wet area.

FloorPly14® Flooring Span Table

| Application | UDL (Kpa) |

CONC (kN) |

Sheet Length m |

Span (mm) | ||||

| 15mm | 17mm | 19mm | 21mm | 25mm | ||||

| Domestic flooring and decking | 2.0 | 1.8 | 2.4m | 400 | 480 | 600 | 800 | 800 |

| Office | 3.0 | 2.7 | 2.4m | 343 | 400 | 480 | 600 | 800 |

| Retail | 4.0 | 3.6 | 2.4m | 343 | 400 | 480 | 600 | |

| Industrial | 5.0 | 4.5 | 2.4m | 343 | 480 | 600 | ||

| Domestic Garage | 2.5 | 9.0 | 2.4m | 300 | 343 | 480 | ||

FloorPly14® Roofing Span Table

| Application | UDL (Kpa) |

CONC (kN) |

Sheet Length m |

Span (mm) | ||||

| 15mm | 17mm | 19mm | 21mm | 25mm | ||||

| Light roof 0-10° | 0.25 | 1.1 | 2.4m | 900 | 900 | 900 | 1200 | 1200 |

| Light/Heavy roof 10-20° | 0.25 | 1.1 | 2.4m | |||||

| Light/Heavy roof 20-30° | 0.25 | 1.1 | 2.4m | |||||

| Light/Heavy roof 30-45° | 0.25 | 1.1 | 2.4m | |||||

| Light roof up to 10° | 0.25 | 1.8 | 2.4m | 800 | ||||

Product Literature:

Certificates:

Get in touch:

I-Built products are available on order from all major building supply outlets throughout New Zealand. Please feel welcome to request product samples - or additional information - using the enquiry form below:

Gallery

CAD Details

Start using our products in your designs. Download CAD files or PDFs of construction details for our product range Search & download

Product Brochures

Download PDF versions of our latest brochures to make selecting the right product easy. Browse our selection

Design & Layout Service

Need help? Make use of our experienced design & layout team for your next project Learn more