Case Studies | Home-Made MultiStrut Floor Joists

After the US construction industry expanded by 62% and New Zealand and Australia were short-supplied IBeam floor joists, our team set about to find a clever alternative. Our solution was to invest in machinery so we could manufacture our own MultiStrut floor joists in-house with easily accessibly materials.

We were up and running in May and a Generation Homes house was one of the first to use the new joists. Brent McMillan, the project manager for that build, said that reliable supply was only one of the upsides.

“I’d heard about this product, but to be honest we first went to it because of the supply issues,” says Brent. “But now, personally, I wouldn’t go back.”

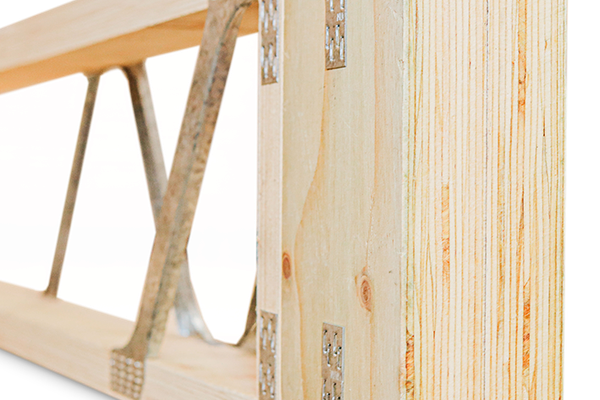

Steel webbing for better flexibility

A key benefit for Brent was the steel webbing, which offered far more flexibility – and minimised cutting on site.

“There’s so much space. You can run all the pipes, cabling and wires anywhere you want without having to drill. With the previous product, you could only cut through the web at certain points,” he explains.

That creates a positive knock-on effect, making the whole project more efficient.

“It just makes things so much easier,” says Brent.

No supply issues

The key benefit, of course, is that there’s little danger of running into supply issues with MultiStrut – there’s stock sitting on the shelves.

“It’s a really good way to keep jobs moving forward when supply issues come up.”

Lightweight and easy to handle

Brent has heard from the builders on-site that the MultiStrut’s lightweight design makes it far easier to handle.

“It’s easy to manoeuvre around the site. That makes the job quicker and easier for the builder.” This includes the MultiStrut joist being able to be trimmed with conventional tools on site up to 300mm.

Off-the-shelf lengths minimise cutting

MultiStrut joists make things efficient to install. Our design team work with Generation Homes to make sure they can use off-the-shelf lengths. This means less waste, a fast install and more cost-efficiency.

Working with NZWOOD “seamless”

Behind the great new product is also a team of people that Brent says made things seamless.

“NZWOOD is great. It’s been seamless with IBuilt – they’ve really hit the ground running.”